What is the difference between DTF film and DTF paper?

Today, with the rapid development of digital printing technology, DTF (Direct To Film) film and DTF paper are widely used in the field of clothing and textile as two important alternative consumables for DTF printing. Although they are all designed to meet the needs of digital printing, there are significant differences between the two in terms of material, application, performance and so on. In this Paper, the differences between DTF membrane and DTF paper will be discussed in detail from multiple perspectives.

Contents

1. Material and structure

DTF membrane

DTF Film, full name of Digital Transfer Film, is a special transparent film, mainly used in DTF (direct film) printing process. DTF film is usually composed of multi-layer structure, including base layer, release layer, adhesive layer, printing layer, protective layer and antistatic layer. The design of this multi-layer structure enables the DTF film to better adapt to different materials and printing requirements during the printing process.

Base layer: provides strength and stability of the film.

Release layer: After printing is completed, it is convenient to transfer the pattern from the film to the target material.

Adhesive layer: ensures that the pattern adheres firmly to the target material.

Printing layer: Used to receive ink or pigment to form the desired pattern.

Protective layer: protect the printing layer from the damage of the external environment.

Antistatic layer: prevent static electricity in the printing process, affecting the printing quality.

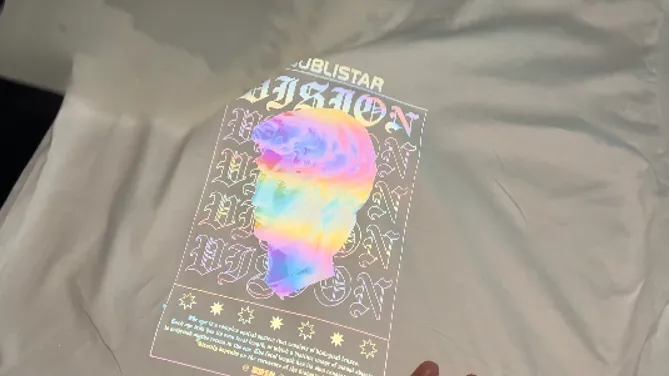

According to the different release process, DTF film can be divided into hot tear film and cold tear film, there are more types of characteristic film. Hot tear film is suitable for large patterns and lower printing temperatures, while cold tear film is suitable for more types of fabrics, with higher long-term washing fastness and lower cost. The main feature films are: temperature variable film, luminous film, flash film, DTF rainbow reflective film, laser film and so on. The above feature film is very suitable for personalized customization, so that people have a bright feeling!

The above characteristic films need to be printed according to the time and temperature specified by the manufacturer, and operate in strict accordance with the specified humidity and temperature to avoid the phenomenon of poor printing effect caused by excessive temperature and humidity.

DTF paper

In contrast, DTF paper is not a thin film material, but refers specifically to paper or paper-like substrates used in the DTF printing process. DTF paper usually has high ink absorption ability and good printing adaptability, which can meet the high definition and high resolution requirements of digital printing.

After all, DTF paper is paper. After melting and drying in the oven, it is necessary to adjust the temperature or control the time of DTF transfer paper in the oven in time to avoid burning or burning of DTF paper due to too long time.

DTF paper printing environmental conditions are generally controlled to about 30% to 60% humidity, indoor temperature control at 20-30℃.

If the machine is used in the winter when the temperature is low, for example, when the humidity is greater than 70%, we can use the DTF printer to heat before and after and remove the excess water in the DTF paper to ensure stable quality. In the case of appropriate air humidity, we do not need to open before and after heating, so as not to arch the paper and wipe the nozzle. In addition, it is recommended to heat the plate of DTF shake powder machine to 40-50℃.

Generally, the baking speed after shaking powder is appropriate to match the printing speed, and the temperature is best to warm first and then heat the stepped tunnel oven, and it is appropriate to control the temperature of the DTF paper table between 70-90℃. Let’s turn on the DTF powder shaker and set the temperature to 80 degrees.

2. Application and performance

Application field

Because of its excellent performance and wide range of applications, DTF film occupies an important position in the printing industry. It is widely used in a variety of fabrics, such as cotton T-shirts, canvas, flannelette, cotton and linen, silk, polyester, lycra and other fabrics. DTF printing has a wide application prospect in the field of garment and textile.

DTF paper is mainly used in the need for high definition, high resolution printing, better transfer some small and delicate patterns and designs. The finished product of DTF transfer paper is colorful, the quality is very stable, the performance is superior, and the most important thing is environmental protection and non-toxic. Suitable for transfer printing, ironing, all kinds of clothing transfer trademarks, transfer patterns, washing labels, personalized DTF printing, etc. It can be used for DTF covering printing and shirt fabric of different textiles such as T-shirts, cut pieces, etc., especially suitable for small and medium-sized mass production.

Performance characteristics

Washing fastness: DTF film, especially cold tear film, has high washing fastness and can maintain the integrity and clarity of the pattern after multiple washes. The washing fastness of DTF paper is relatively low, and it is more suitable for occasions where frequent washing is not required.

Adhesion: The adhesive layer of DTF film can ensure that the pattern adheres firmly to the target material and is not easy to fall off. DTF paper relies on the ink absorption capacity of its surface and the printing process to ensure the adhesion of the pattern.

Adaptability: The multi-layer structure of DTF film allows it to adapt to different types of fabrics and materials, with higher flexibility. DTF paper, on the other hand, is relatively simple and more suitable for small trademarks.

The degree of oil return: the material of DTF film determines the characteristics of oil return, and DTF paper does not appear. At present, many DTF manufacturers have been working on solving this problem, and the adverse effects have been minimized.

Printing without white edge: In the early or the designer or the operator’s mistake, DTF film transfer is extremely easy to appear white edge, DTF transfer paper hot clothes feel good, no color virtual edge. Done absolutely without limits.

Environmental recycling: Early DTF membrane is also environmentally friendly, but at present, it is difficult to achieve recyclable and recyclable. But DTF transfer paper is indeed recyclable, and coating upgrades save energy consumption.

3. Cost and market

Cost analysis

Because the production process of DTF film is relatively complex and has high material requirements, its cost is usually higher than that of DTF paper. Especially in mass production, the cost advantages of DTF membranes may be more obvious. However, in some specific cases, such as the need for high definition, high resolution printing or the need for high washable fastness, the cost advantage of DTF film may be compensated.

Due to its relatively simple production process and low cost, DTF paper has greater competitiveness in the low-end market and FMCG market.

Therefore, how to choose DTF film and DTF paper is best to decide according to the product you need to transfer, and the most suitable is the best.